Switch panels are one of the most practical upgrades you can make in a truck. They let you control lighting, accessories, auxiliary power, and other electrical devices cleanly and safely. But like any component, they require proper installation, maintenance, and occasional troubleshooting. In this guide, we’ll cover what switch panels are, how to choose the right one, and how to maintain and troubleshoot your switch panel system in a truck.

What Is a Truck Switch Panel and Why Use One

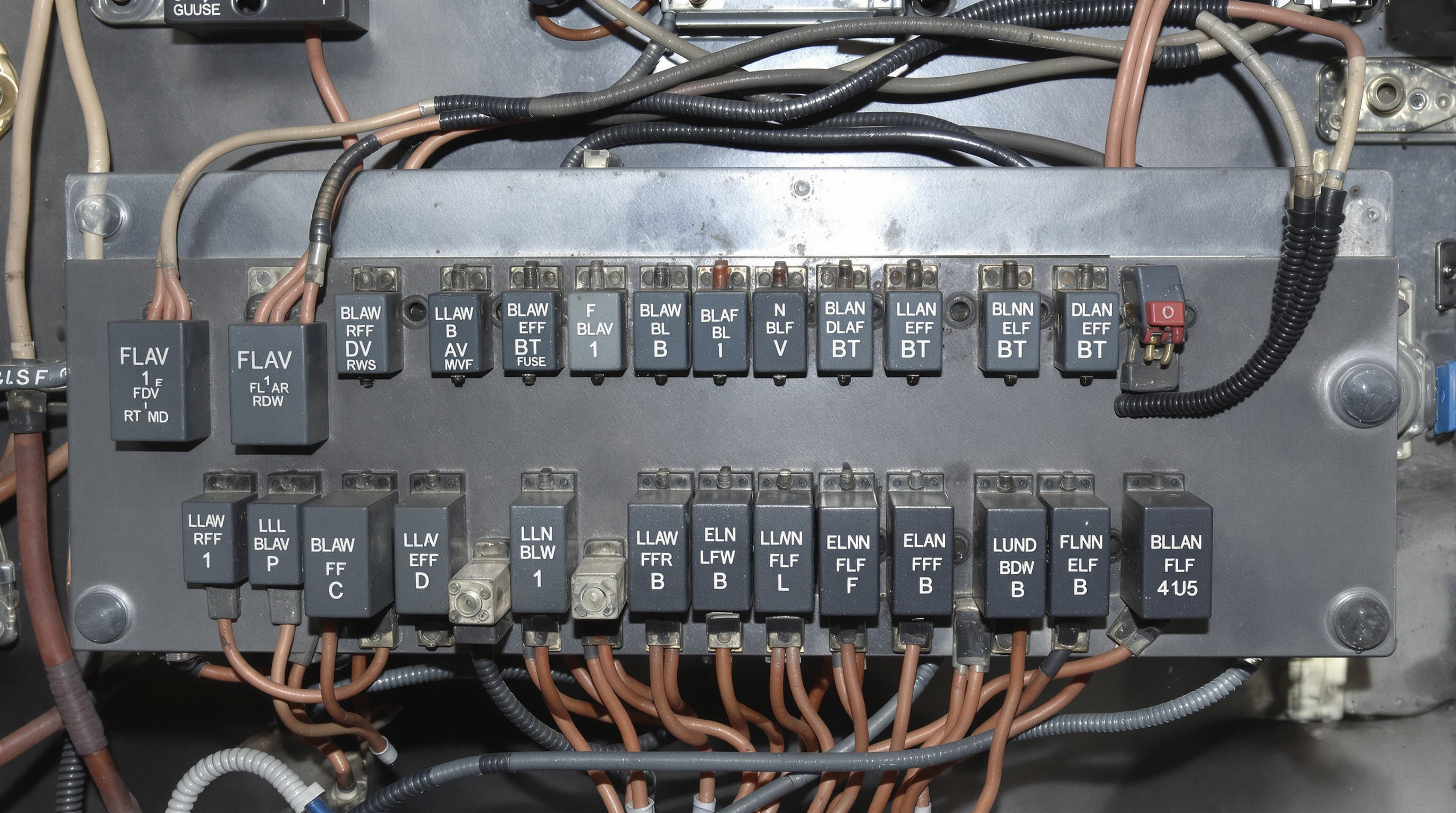

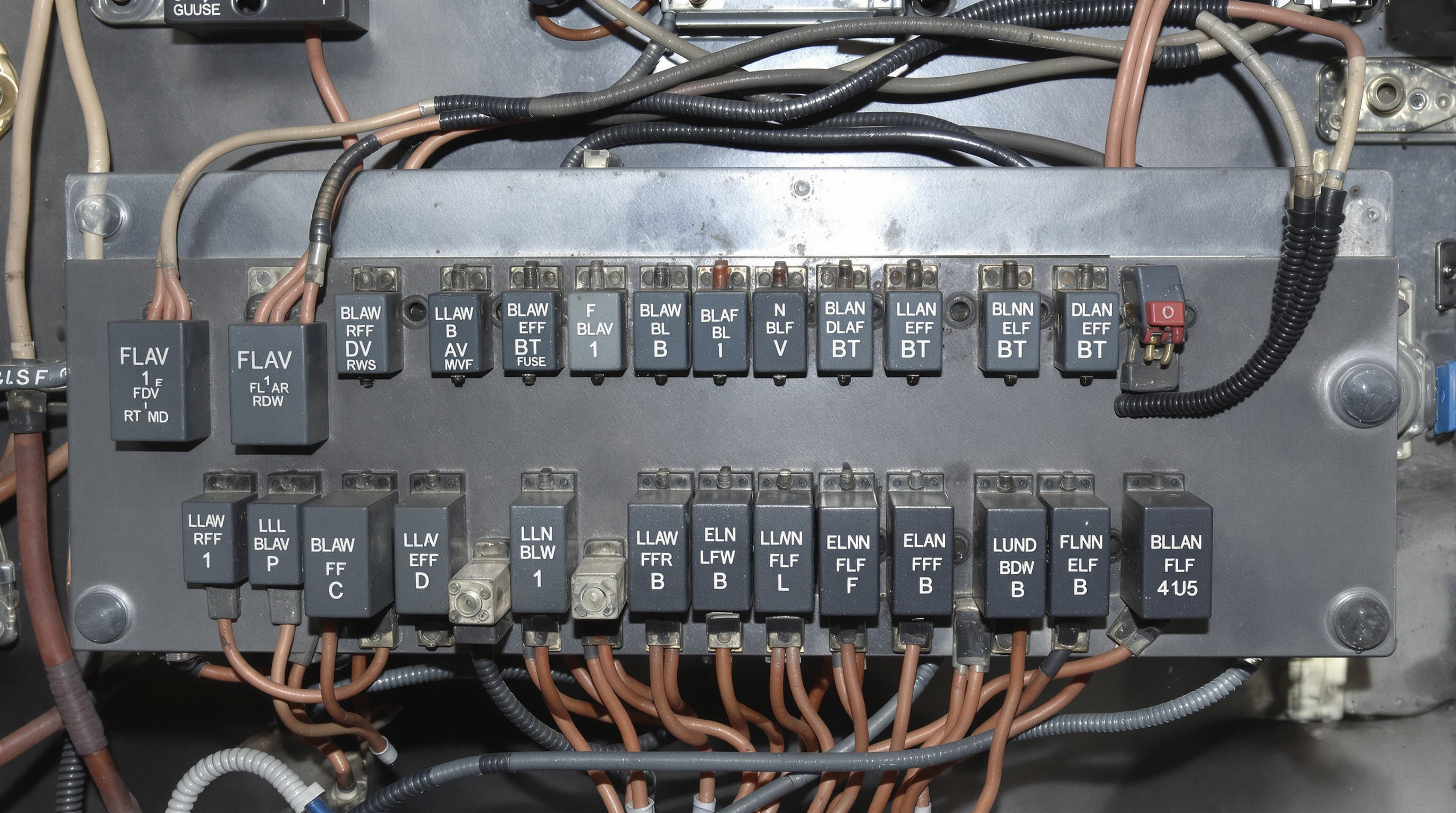

A switch panel is a control interface — usually multiple switches, sometimes with built-in relays, voltmeters, USB ports, circuit breakers, LED indicators — that lets you manage multiple electrical accessories from a single, organized module.

Benefits of a Switch Panel

-

Organization: Instead of adding wires and switches scattered all over the dashboard, panels group everything neatly.

-

Safety: Many panels include built-in protection (circuit breakers, relays) reducing risk of over-load.

-

Convenience: Easy access to operate lights, winches, air compressors, or other add-ons. Panels with LED backlights or RGB options help visibility.

-

Durability and Waterproofing: Panels built to IP ratings (e.g. IP68), solid relays, weather-resistant housings help endure harsh off-road or marine/storm-y conditions.

Switch Panel Series — Examples & Key Features

YUJIEKEJ offers a wide range of switch panels suited to automotive, marine, RV, and off-road use. Their product line includes:

-

6/8/12-Gang RGB Wireless Bluetooth LED Light Bar Control Panel (12V) – allows remote control / RGB lighting, suitable for light bars.

-

Upgraded 6/8/12-Gang Momentary Pulse Relay System Waterproof IP68 – for high water resistance, controlling multiple accessories.

-

4-Gang RGB Dimmable Panel with solid relays and blue LED backlight — good for trucks, boats, etc.

-

4/6/8/12-Gang Rocker Panel with Dual USB & Digital Voltmeter — combines accessory control, USB charging, and voltage monitoring.

-

Panel with Type-C / QC3.0 USB charging — for modern devices.

Notable Features

-

Number of Switches (“Gang”): Ranges from 4 up to 8 in the YUJIEKEJ offerings. Choose based on how many accessories you have now, plus room for future additions.

-

Built-in Relays & Solid Construction: Some panels include relays so the heavy current load is handled properly. Solid materials help with durability.

-

LED Indicators, Backlights, RGB, Dimmable Lights: Helpful for visibility and also aesthetics. Useful in low light or at night.

-

Waterproof Ratings (IP68 etc.): Especially important for trucks used off-road, in wet climates, or for marine use.

-

Additional Ports: USB, Type-C, digital voltmeter readout — allows you to monitor battery voltage and charge devices without extra gadgets

How to Choose the Right Switch Panel for Your Truck

When selecting a switch panel, keep the following in mind:

-

Electrical Load & Current Rating

Make sure each circuit/switch can handle the amperage of the accessory. If you’re controlling high-draw devices (winches, roof lights, compressors), the panel must have appropriate relays or breakers.

-

Number of Circuits Needed

Count all accessories: light bars, work lights, auxiliary outlets, etc. Leave a few spare switches for future upgrades.

-

Voltage Compatibility

Most truck systems are 12V, some 24V in certain trucks or heavy rigs. Ensure the panel supports your system. YUJIEKEJ panels are typically 12-24V options.

-

Mounting & Size / Fit

Panel should physically fit where you plan to mount it. Needs to be accessible and visible. The switch design (rocker, toggle, momentary, pulse) matters for how you operate it, especially if you’ll need momentary/pulse modes.

-

Weatherproofing

For trucks that see rain, mud, snow — or for fishing, marine, or offroad environments — waterproof or at least splash-proof is essential. Panels with IP68 or similar rating are preferable. YUJIEKEJ offers IP68 rated versions.

-

Extras

Things like USB charging, voltmeters, digital displays, LED indicators, brightness dimming can add convenience.

-

Quality & After-Sales Service

Ensure the panel is well built, uses quality components, good sealing. Manufacturer warranty or substitution support matters. YUJIEKEJ highlights quality control, ODM services, after-sell service, and relatively fast lead time.

Maintenance Tips for Switch Panels in Trucks

Keeping your switch panel working reliably involves occasional maintenance. Here are recommended practices:

-

Secure Mounting & Proper Wiring

Ensure the panel and all accessories are grounded properly. Use appropriately sized wires, correct fuses or breakers, avoid sharp bends, protect wiring from abrasion.

-

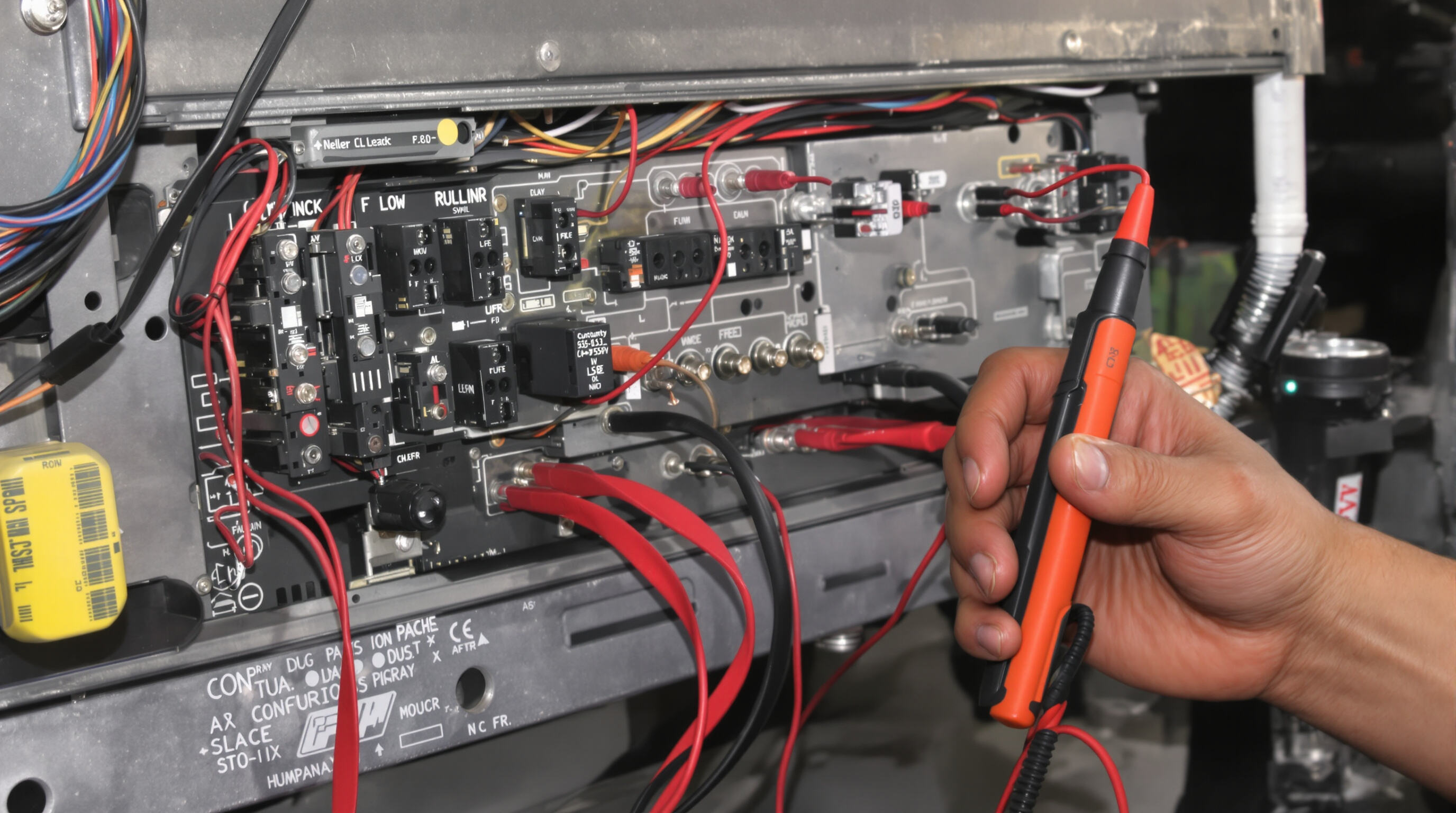

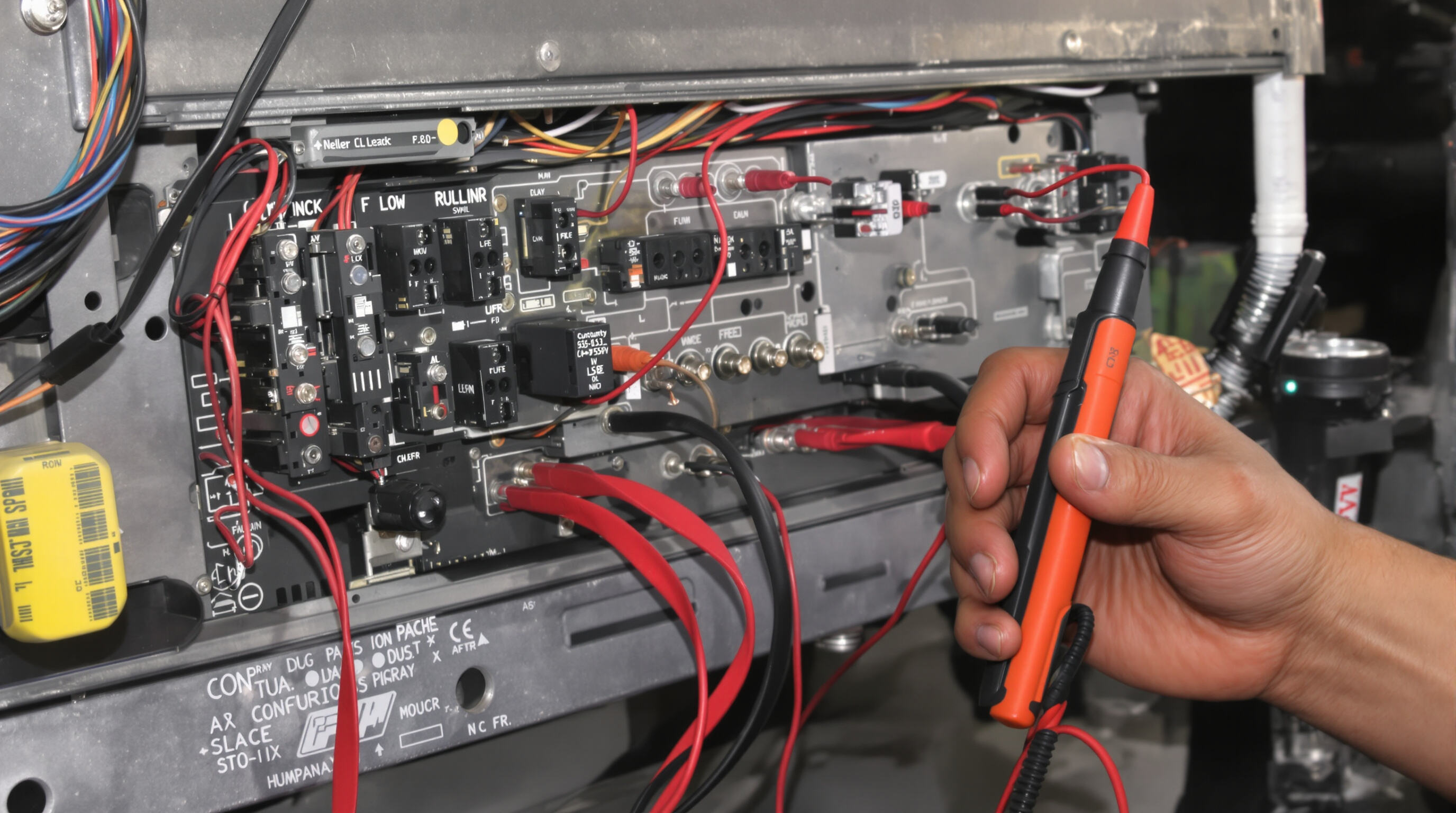

Clean Contacts & Switches

Dirt, corrosion, or moisture buildup on switch contacts, connectors, or relay terminals reduces performance and can cause high resistance, overheating, or intermittent failure.

-

Inspect Seals / Enclosures

If your panel is waterproof, regularly inspect the housing, seal gaskets, plug covers, etc. Make sure nothing is compromised.

-

Check Voltage Drops

Over long runs or in high current circuits, voltage drop can affect performance. Use heavy enough gauge wire. A voltmeter (built into or outside panel) helps you monitor system voltage.

-

Protect from Water & Vibration

For trucks, there’s constant vibration and exposure to the elements. Secure all connectors, use locking hardware if possible. For waterproof panels, ensure proper sealing.

-

Regularly Test Functionality

Turn each switch on/off periodically to ensure they work, check for flickering, heat, or any abnormal sounds from relays.

Installation Checklist

Here’s a simple checklist to ensure your switch panel is installed correctly:

-

Disconnect battery before doing wiring.

-

Plan wiring paths avoiding sharp edges and heat sources.

-

Use proper gauge wires for load (look up draw, add margin).

-

Install in-line fuses or breakers for each accessory if not built into panel.

-

Secure grounds with clean metal contact; paint or rust removed.

-

Seal any holes made for wires; use grommets.

-

Mount the panel in a place easy to reach and see, but protected from direct exposure if possible.

-

Test all switches one by one after installation; check voltage at each output while under load.

When to Replace vs Repair

Sometimes a panel or switch will fail beyond repair. Consider replacing when:

- Multiple switches stop working.

- The enclosure is cracked or sealed parts irreparably damaged.

- Internal components (relays, LEDs) have failed, especially if the cost of repair approaches the cost of a new panel.

High-quality panels — like those from YUJIEKEJ — may offer spare parts or modular components, but in many cases, full replacement may be more cost-effective.

Final Thoughts

Switch panels are a backbone component for managing your truck’s electrical accessories. A good panel — solid construction, waterproofing, the number of circuits you need, proper installation — can make your setup safer, more reliable, and easier to expand. Maintenance and troubleshooting aren’t hard once you know what to look for: clean wiring, good seals, proper voltage, and correct fuse or breaker protection.

If you’re considering upgrading or buying a switch panel, evaluating options like those from YUJIEKEJ (with their range of 4- to 8-gang panels, USB integration, waterproof ratings, etc.) is a great place to start. With the right panel and care, you’ll enjoy years of reliable service, even under tough truck-use conditions.