Sep 12,2025

0

Když jde o ochranu elektrických systémů vozidel, pojistky jsou nepostradatelnými hrdiny elektrické ochrany. Pojistky chrání jakékoli vedení nebo zařízení před poškozením způsobeným přetížením a/nebo zkratem. Nicméně ne všechny pojistky jsou stejné a zatímco standardní nožové pojistky jsou velmi běžné ve většině osobních vozidel, u větších nebo složitějších vozidel (s náročnějšími elektrickými zátěžemi) by bylo výhodné použít vyšší úroveň pojistek – MIDI pojistky.

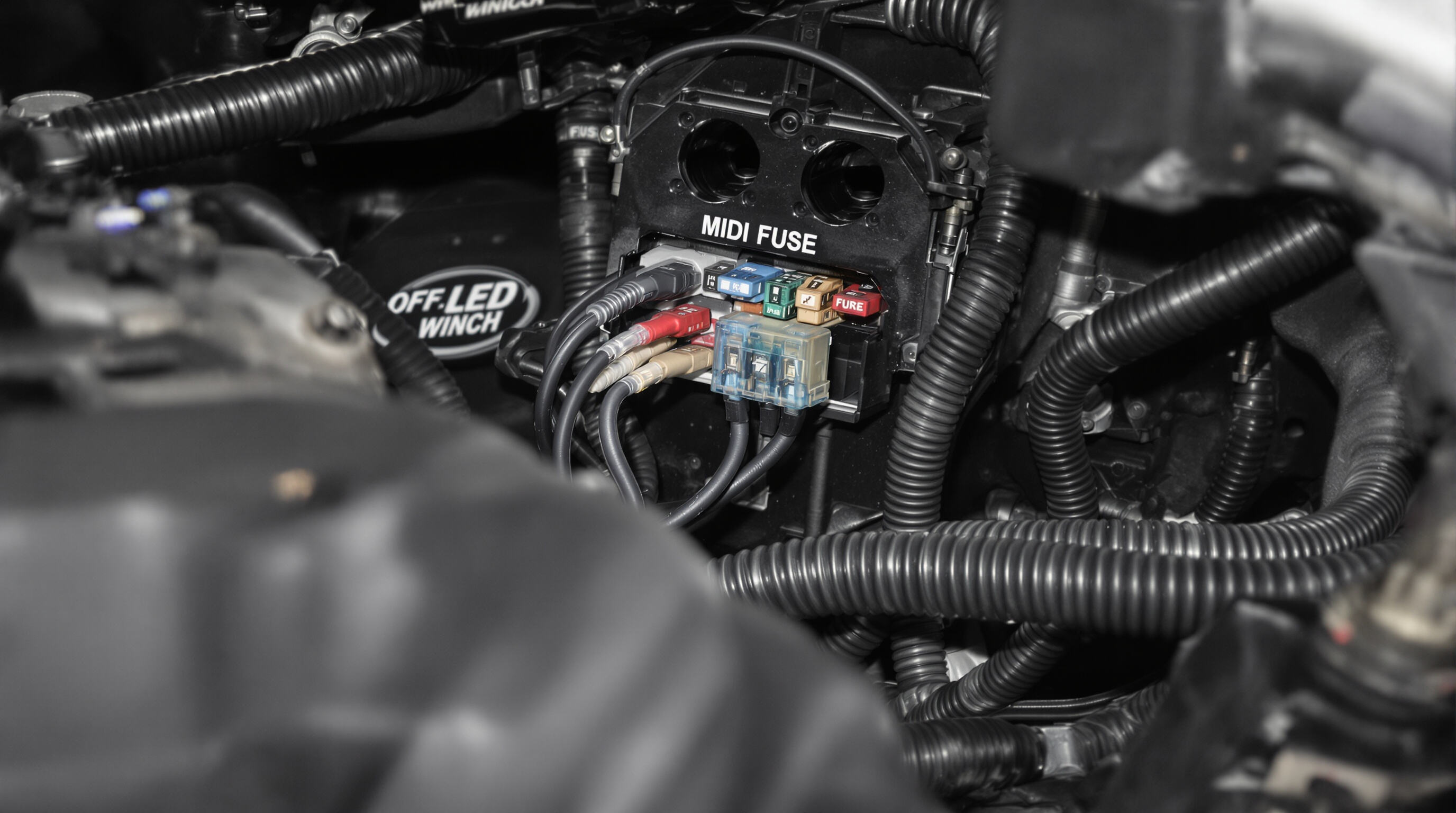

YUJIEKEJ MIDI auto pojistky jsou šroubované pásové pojistky, které jsou navrženy pro vyšší proudy a extrémnější podmínky, než by standardní pojistka typu čepele mohla vydržet. Pro jakékoliv středně cenové doplňkové příslušenství, těžké vybavení, nebo nákladní auto, RV nebo terénní vozidlo, mohou pojistky MIDI pomoci zlepšit nastavení. Pojďme si stručně projednat některé z hlavních výhod používání MIDI automatických pojistek, spíše než standardních automobilových pojistek. Poté si uděláme poznámky o používání, spolehlivosti a údržbě a pomůžeme vám najít správnou cestu k jejich implementaci.

Před tím, než se podíváme na výhody, je důležité pochopit, co jsou MIDI pojistky.

A MIDI pojistka je kompaktní, šroubovací pojistka, která je obvykle určena pro 30A až 200A (někdy vyšší) - Ne, ne. Místo aby se připojovala do otvoru jako pojistka, je připevňována na šrouby nebo šrouby pomocí matic, což poskytuje pevné mechanické a elektrické spojení.

Často se vyskytují v:

MIDI pojistky jsou konstrukčně určeny pro vyšší proudovou ochranu než standardní automobilové nožové pojistky, které obvykle dosahují maximálně 40 A nebo 50 A.

Jednou z nejzřejmějších výhod MIDI pojistek je jejich kapacita proudu .

To je činí ideálními pro obvody napájející náročné příslušenství, jako jsou dodatečně instalované zesilovače, systémy pomocných baterií, lednice, měniče nebo navijáky.

Použitím pojistky MIDI můžete s jistotou chránit silnoproudé obvody, aniž byste riskovali přehřátí nebo předčasný výpadek, který může u standardních pojistek při takovém zatížení nastat.

Další klíčovou výhodou je šroubovací konstrukce .

Standardní pojistky spoléhají na tlakové upevnění uvnitř plastového držáku. V průběhu času může vibrace, tepelné cykly nebo koroze způsobit oslabení kontaktu. Špatný kontakt vede ke zvýšenému odporu, který může generovat teplo a nakonec způsobit poruchu.

Pojistky MIDI jsou naopak upevněny maticemi na svorky . To zajišťuje:

U nákladních vozů, které denně jezdí po nerovných cestách nebo na staveništích, představuje mechanická bezpečnost MIDI pojistky velké vylepšení.

I když MIDI pojistky zvládají mnohem vyšší proudy, jsou překvapivě kompaktní. Zabírají relativně málo místa, což umožňuje jejich montáž do těsných prostorů motoru nebo v blízkosti bateriových boxů, aniž by zabíraly příliš mnoho místa.

Na rozdíl od větších ANL nebo pojistek třídy T, MIDI pojistky kombinují ochranu proti vysokému proudu s menším a cenově výhodným provedením . To je činí ideálními pro použití v nákladních vozech a obytných vozidlech, kde záleží na efektivním využití prostoru.

Teplo je největším nepřítelem pojistky. U standardních nožových pojistek se malá plocha kontaktu v držáku může zahřát, když je obvod blízko své meze. V průběhu času toto teplo degraduje jak pojistku, tak její držák.

Pojistky MIDI mají větší plochu a pevné kovové kontakty které rovnoměrněji rozvádějí proud. Šroubovací připojení také minimalizuje odpor, což znamená menší tvorbu tepla.

Výsledkem je, že pojistky MIDI udržují vysoký výkon a dlouhou životnost i v náročných podmínkách, kde nelze vytvoření tepla vyhnout, například pod kapotou nebo v blízkosti center pro distribuci energie.

Vozidla jako terénní nákladní automobily, obytné vozy a lodě jsou často vystavena prachu, nečistotám, vodě a vibracím. Standardní nožové pojistky umístěné v plastových držácích nemusí těmto podmínkám vždy dostatečně odolat.

Pojistky MIDI, díky svému utěsněnému šroubovacímu provedení, jsou mnohem odolnější vůči vnějším zátěžím . Ve spojení s vhodnými držáky nebo rozváděcími bloky poskytují robustní řešení, které zůstává spolehlivé i v extrémních klimatických podmínkách.

U námořních aplikací, kde koróze představuje stálé riziko, jsou pojistky MIDI preferovanou volbou díky svým pevnějším, utěsněným spojům.

Další výhodou pojistek MIDI je jejich snadná integrace do modulů rozvodu proudu . Mnoho dodatečně instalovaných pojistkových desek a sériových systémů používá pojistky MIDI jako centrální distribuční body pro více obvodů.

Například nákladní automobil vybavený přídavným osvětlením, ledničkou a 12V měničem může využívat distribuční blok MIDI, kde je každý obvod chráněn pojistkou MIDI s odpovídajícím jmenovitým proudem.

Tato centralizace zajišťuje čistší zapojení, jednodušší odstraňování závad a zaručuje, že každé příslušenství má svou vlastní správně dimenzovanou ochranu.

Protože pojistky MIDI jsou navrženy pro vyšší zátěž, jsou méně náchylné k předčasnému selhání, pokud obvody běží trvale blízko své kapacity. Běžná pojistka provozovaná těsně pod svým limitem se může rychleji opotřebovat, zatímco správně dimenzovaná pojistka MIDI vydrží mnohem déle.

To se promítá do menšího počtu výměn, kratších prostojů a sníženého rizika neočekávaných poruch — což je zvláště důležité u nákladních vozidel nebo obytných vozidel na dlouhých cestách.

Na první pohled MIDI pojistky stojí více než běžné nožové pojistky. Jejich hodnota však spočívá v ochraně a dlouhé životnosti, kterou poskytují. hodnota spočívá v ochraně a dlouhé životnosti, kterou poskytují. .

Opakovaná výměna spálených nožových pojistek nebo ještě hůř – oprava poškozeného vedení kvůli poddimenzované pojistce – vyjde mnohem draže než počáteční investice do správné MIDI pojistky.

Pro každého, kdo provozuje zařízení s vysokým odběrem proudu, je malá dodatečná počáteční cena MIDI pojistky více než ospravedlněna její spolehlivostí a bezpečností.

Níže jsou uvedeny konkrétní příklady, kdy je vhodnější použít MIDI pojistku namísto standardní:

Použití MIDI pojistek neznamená, že není třeba pravidelná údržba. Následují osvědčené postupy:

Zatímco běžné nožové pojistky stále mají své uplatnění v každodenních osobních vozidlech, YUJIEKEJ MIDI automobilové pojistky jsou chytřejší volbou pro nákladní automobily, obytná vozidla, terénní vozy a jakékoli vozidlo s náročným příslušenstvím . Jejich vyšší proudová zatížitelnost, pevnější šroubovací připojení, kompaktní, ale odolný design a odolnost v extrémních podmínkách je činí mnohem lepšími ve srovnání s běžnými pojistkami.

Přepnutím na MIDI pojistky v odpovídajících aplikacích nejen chráníte svou investici do příslušenství, ale také zajišťujete celkovou bezpečnost a spolehlivost elektrického systému vozidla.

Když záleží na spolehlivosti – ať už poháníte naviják na blátivé cestě nebo provozujete měnič napětí ve vozidle pro rekreační účely – MIDI pojistky poskytují klid v duši, který běžné pojistky prostě nemohou nabídnout .